Efficiency and accuracy are at the core of enterprise labeling in global supply chains. The complexities of global labeling requirements and regulations can be a challenge for enterprise organizations who often have to communicate important information on their labels, and in multiple languages, such as:

- Ingredients

- Warnings/safety information

- Product details

- Customer data

- Brand information

- Regulatory information

With the vast amount of information required, organizations must define an effective barcoding and labeling process that creates, automates and manages the labeling to enhance security, safety and accuracy.

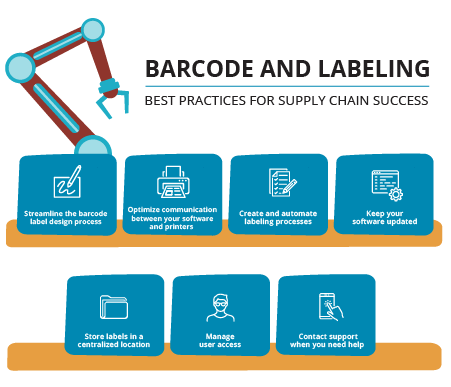

The following best practices will facilitate better management of labeling regulations, processes and communication across your supply chain.

Barcoding and labeling challenges facing supply chains

Before addressing best practices for barcode and label management, here are a few common labeling challenges that many enterprise organizations face across their global supply chain:

- Product labeling errors: misplaced or damaged barcodes, incorrect data and poor printing can lead to costly recalls, reprints and inefficiencies that affect the entire supply chain.

- Localization: meeting requirements and regulations in specific countries and/or regions is important to ensure proper information is communicated in the correct language and style.

- Poor supply chain visibility: labeling processes are siloed between different stakeholders making for an inefficient and often redundant process.

- Expanding business: when an organization expands into new regions, whether through manufacturing or distribution, it adds further labeling complexities.

- Evolving regulations and requirements: each industry is constantly evolving to include new requirements for labeling to address regulatory standards or industry-specific nuances that need to be accommodated.

The following sections identify opportunities for improving your labeling process to ensure these challenges don’t affect your supply chain.

1. Streamline the barcode label design process

It’s important to choose software that is accessible to users, easy to learn, easy to use, and effective to keep your supply chain running smoothly. Labeling software with features like a Windows interface and intuitive design make the barcode and label design process simple and streamlined from the beginning, ideal for complex labeling environments.

You can take advantage of enterprise labeling software features that support design layers. These hold different kinds of information and variable data, and then either include or hide each layer based on user-defined conditions when a label is printed. Automating your labeling process by using design layers and conditional printing, can dramatically reduce the number of label files you need to create and manage, saving time, money and resources.

With BarTender®, there are unique design features that allow for quick printing adjustments, such as:

- Auto-size text

- Nonstandard serialization schema

- Scripting logic

- Source images as data

- Create advanced date / time formats

While barcodes or labels may be designed by one organization, designs move through suppliers, distributors and manufacturers. With so many players in the labeling game, it’s more likely for there to be errors or compliance violations that can be costly.

Integrating supply chain systems used with barcode software for enterprise businesses, helps to quickly and accurately:

- Populate product descriptions and expiration dates

- Calculate and generate barcodes and RFID

- Create labels that comply with industry standards

- Group labels in a single template

- Make global changes across the supply chain

For example, one chemical manufacturer needed its hazard labeling to comply with the regulations of eight different countries. Instead of building and maintaining eight individual label formats, they built a single format in which each country’s data fields and layout were stored on a separate layer. At print time, a rule in the label chose the appropriate layer to print based on the product's destination.

2. Optimize communication between your software and printers

Optimizing the communication between your software and printers increases overall supply chain and labeling efficiency. It’s also important to maintain security when information is traveling across networks and to help prevent printing errors.

Secure printing with enterprise barcoding and labeling software enables organizations to have:

- Completely control printing with online approvals

- Secure labeling with SSL encryption and role-based access that provides superior security

Print operators can use BarTender’s forms-based interface to access a dropdown menu of forms for labels, so they never need to access the label design, offering increased accuracy and system security.

Implementing an enterprise labeling solution helps prevent printing errors by directly communicating with data sources. In doing so, labeling software accurately calculates barcodes for efficiency and to prevent errors. After information is populated, labeling software then communicates with the corresponding printer, anywhere in the world, sending the label to that location.

3. Create and automate labeling processes

When each part of your supply chain has different labeling processes and procedures, it can create inefficiencies and errors that slow down production and delivery and may affect brand credibility.

By creating a comprehensive labeling process, enterprise organizations can feel confident about product labeling across the supply chain, ensuring regulatory compliance and customer satisfaction.

BarTender creates and automates labeling for enterprise organizations using powerful features such as configurable workflows. These allow you to define document states and transitions to manage the barcoding and labeling process, beginning at the design stage all the way to print approvals. The following features will help to increase the quality of label production and enable end-to-end project tracking:

- Easily design custom workflow models specific to business needs with an intuitive, visual drag-and-drop interface

- Create workflows for specific file types, or for files housed in specific folders in the Librarian document management system

- Maintain control over user access (who will design, who will print, who will review/approve) and advance files through the workflow at each state

- Generate automatic email notifications to specific recipients, which triggers when files move between workflow steps

- Simple review and approval process of BarTender documents for production from any web browser, device or operating system (Windows, Android, iOS) that’s connected to the internet, anywhere in the world

Once you’ve established an effective labeling process, it’s important to standardize its use across the supply chain to prevent future challenges.

4. Keep your software updated

No matter what labeling software, devices and other systems you use, staying up-to-date on supported versions is important for maintaining the security and accuracy of enterprise labeling. By updating software systems and devices across the supply chain, you can:

- Fix or resolve issues with previous or outdated versions

- Install patches to resolve potential vulnerabilities where hackers can gain access

- Add features that will improve processes

- Improve compatibility with devices, systems and applications in your network

- Enhance and streamline user experience

5. Store labels in a centralized location

Centralization makes for more effective data management. Without centralized control of a labeling system, data can become confusing and quickly spiral out of control.

Storing label files in a centralized location helps save time and money, reduces errors, improves efficiency and ensures regulatory compliance. A few advantages of centralized label management include:

- Virtually instantaneous global change management for pricing, data and format edits as market and regulatory conditions change

- Reduction of redundant or duplicated activities to increase accuracy

- Automated management and monitoring of serialization for better supply chain visibility

- Data accuracy — the right data is linked to the right label

- Label templates that contain business rules to enable compliance

6. Manage user access

No matter the size of your organization, it’s crucial to know who is accessing label files at every point in the process. Not only is it critical for maintaining barcoding and labeling accuracy and efficiency, it’s essential for regulatory compliance.

Enterprise labeling software like BarTender offers layered security settings such as role-based permissions and encryption to gain granular control over who can open files and who can edit or print labels.

BarTender also provides full audit trails and captures e-signatures to comply with regulations such as FDA 21 CFR Part 11. These features let you know who accessed a label, what edits were made, and where and when a label was printed. For industries like medical devices and pharmaceutical manufacturing, this regulatory compliance is essential for maintaining safety and security.

7. Contact support when you need help

Even if you’re using barcode best practices and a comprehensive labeling solution, support may still be needed. It’s crucial to choose labeling software that provides support where you need it and when you need it, whether it be resources to walk you through processes, or technical support for troubleshooting assistance.

BarTender’s legendary support includes email for non-urgent questions, phone (Standard and Premium plans) for immediate help with troubleshooting, or online chat that uses automated translation to help you resolve simple fixes.

Additionally, BarTender maintains a collection of knowledge-based articles, white papers, blog articles and product help on their website. Through these resources, you can quickly gain access to detailed information to walk you through processes and product information that keeps labeling moving.

Find which BarTender version is right for you

Labeling is an essential part of many business functions, whether a small or large operation. BarTender is proud to offer label and barcode software for large organizations and small businesses, with features uniquely designed for your business needs from global supply chain management to regulatory compliance.

To learn more about which BarTender version is right for you, contact us and continue reading our guide on how to streamline your barcoding and labeling practices.