BarTender Survey Results

9 ways companies are safeguarding against future supply chain disruptions

SEPTEMBER 21,2021

Has COVID-19 served as a catalyst to force companies to rethink their supply chains? While supply chain transformations often happen over long periods, the pandemic pushed businesses to adapt and change rapidly. It also exposed vulnerabilities that organizations may not have previously been ready to acknowledge or act upon.

Regardless of how operations functioned before COVID-19, what has become increasingly clear is that safeguarding the supply chain against future disruptions is a business imperative that positively affects organizations beyond a pandemic.

As McKinsey & Company states, “Actions taken now to mitigate impacts on supply chains from coronavirus can also build resilience against future shocks.”

To better understand the impact of COVID-19 on the supply chain and what actions companies are taking to safeguard the supply chain against future disruptions, we conducted a survey.

One of the biggest takeaways was that 89% of participants surveyed say their company has either created a contingency plan that has been fully implemented or partially implemented due to the COVID-19 disruptions. Another 9% have not created a contingency plan yet but plan to in the future, and only 2% of survey participants reported their company does not plan to create a contingency plan.

With an overwhelming majority of companies taking immediate action to safeguard the supply chain, we thought it would be interesting to know what actions these organizations are taking.

Here, we discuss the key findings of our survey.

Survey Methodology

Our online survey included 600 participants who live in the United States and work at an enterprise-level company (above $500 million) within the supply chain, regulatory, technology, manufacturing, or similar sector.

Survey participants self-identified as holding a job related to the following job titles:

- CTO: 5.67%

- CSCO: 4.5%

- VP/Director of IT: 24%

- VP/Director of Supply Chain: 10.17%

- VP/Director of Regulatory: 5.83%

- VP/Director of Operations: 11.33%

- Other: 38.5%

Our survey sample included a range of participants from smaller companies to large organizations with the following number of employees:

- 0-500: 19.17%

- 501-1,000: 26%

- 1,001-5,000: 23.67%

- 5,001-10,000: 12.5%

- More than 10,000: 18.67%

How COVID-19 impacted the supply chain

Whether companies experienced the impact of COVID-19 directly or indirectly, the pandemic took a substantial toll on company supply chains. Fortune’s report found that “94% of the Fortune 1000 [were] seeing coronavirus supply chain disruptions” in early 2020. The extent of these disruptions varied in scope and timeframe, with some supply chains shutting down entirely while others were unable to source materials to meet customer demand.

Shutdowns occurred due to several reasons, including an inability to provide adequate personal protective equipment to employees, a lack of raw materials or a drop in sales. Regardless, these shutdowns certainly had a ripple effect on many people, products and across industries.

While over the years, many companies spent time, effort and substantial investment creating complex global supply chains, they may not have anticipated what could potentially go wrong. In response to unexpected events of the global pandemic, companies are taking action to safeguard against future disruptions.

Let’s explore the 9 ways businesses are planning for the future based on our survey results.

1. Improving partner and supplier relationships

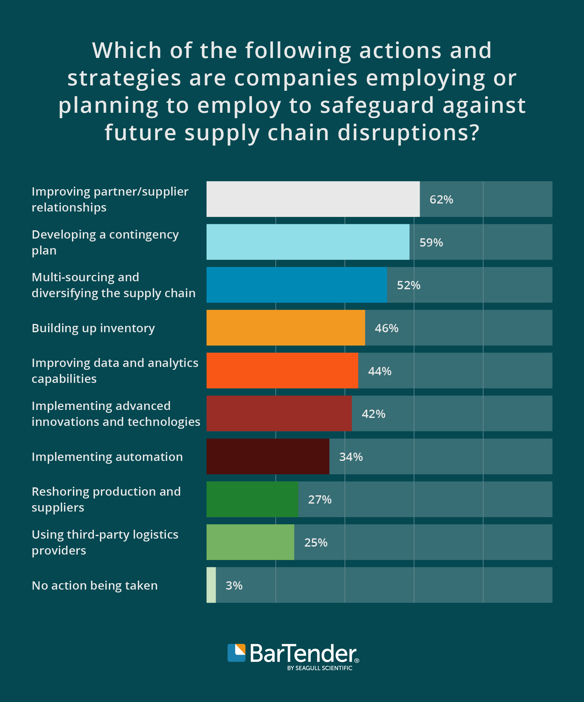

Regarding strategies companies are employing or planning to employ to safeguard against future supply chain disruptions, our survey uncovered that improving partner and supplier relationships is the most common, followed by developing a contingency plan. Only 2.67% of respondents said there is no action being taken, underscoring the industry-wide trend of acting on recent events.

According to Miguel Cossio, a Gartner supply chain analyst, Gartner defines supplier relationship management as “a deliberate enterprise strategy designed to increase collaboration with the supply base.” Although supplier relationship management has always been crucial to an effective supply chain, the events of COVID-19 emphasized the importance of strong relationships and alignment among everyone involved in the supply chain.

This added emphasis seems to have led companies to focus on their supplier relationship management at the strategic level.

2. Increasing focus on sales and operations planning

When asked about the kind of analytics actions and strategies companies are employing to safeguard against future supply chain disruptions, participants surveyed noted an increased focus on sales and operations planning followed by capacity planning.

Sales and operations planning, or S&OP, is known to be a challenging part of any business because it involves components and people both within the supply chain as well as outside of the supply chain that all need to work together cohesively. Recent disruptions seem to have highlighted the importance of improving the S&OP process to both safeguard the supply chain as well as increase revenue and profitability.

3. Investing in tools that provide increased supply chain traceability

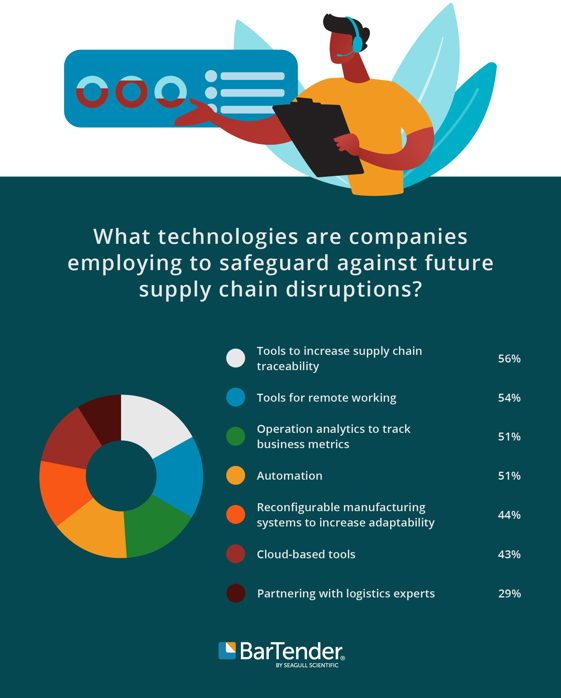

In response to our question about what technologies companies are employing to safeguard against future supply chain disruptions, participants surveyed noted tools to increase supply chain traceability are a priority.

Companies no longer see improving supply chain transparency as optional. As David Linich with Deloitte states, “Transparency goes beyond gaining visibility into the extended supply chain. It is the process by which a company takes action on the insights gained through greater visibility in order to manage risks more effectively.”

Also significant is an increase in tools for remote working now that more of the workforce is working remotely than ever before. Our survey revealed that 52.5% of participants said their company shifted from an in-person environment to a more distributed or remote model of business following the events of 2020.

This abrupt transition required organizations to quickly pivot, source and implement tools that enable workers to perform the same tasks from a different location. Adapting to a new work environment became imperative.

4. Utilizing automated technologies such as cloud logistics

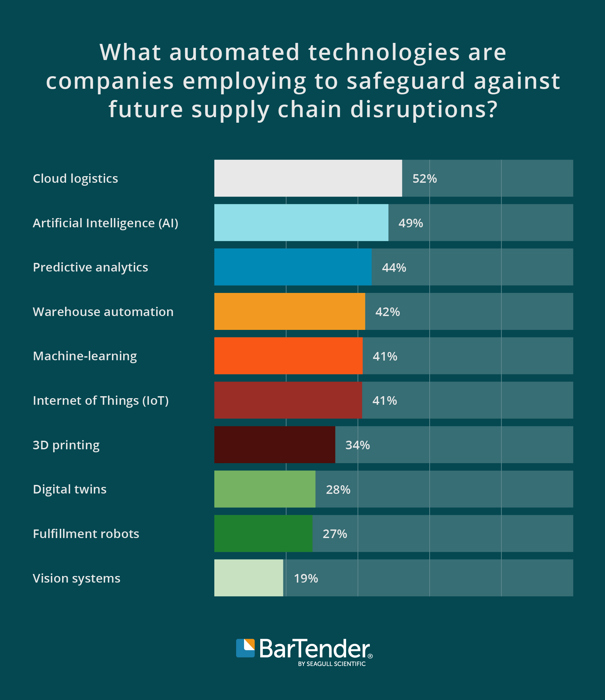

Regarding automation technologies companies are employing to safeguard against future supply chain disruptions, participants surveyed noted cloud logistics and artificial intelligence as the top two.

An increase in digitization or automation has the potential to vastly improve efficiencies and the time it takes from end-to-end of the supply chain. Per Gartner, “over the next couple of years, more than 80% of organizations plan to develop the capabilities for a digital ecosystem…to support the most critical future supply chain strategies – resilience, agility and purpose-driven organizations – and ultimately to improve the customer experience.”

5. Reshoring production and sourcing to reduce risks

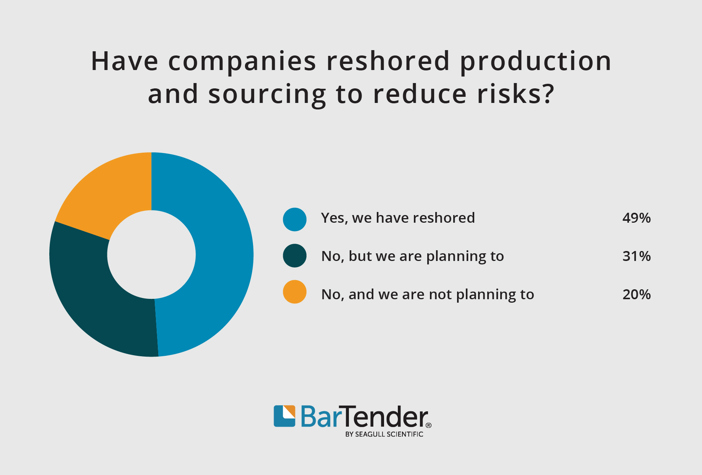

Our data found that 80% of participants surveyed noted that their company has reshored or is planning to reshore production and sourcing to reduce risks in the future. Efforts to reshore target specific goals: better control, efficiency and stability of the supply chain.

As supply chains continue to become more complex, analyzing systems and suppliers that are often involved in a global marketplace becomes a means of reducing supply chain risks and improving resiliency.

Many companies and, as a result, many consumers experienced the negative effects of production lines halting due to COVID-19. The need to reshore or diversify supplier bases to avoid delays or interruptions to the supply chain became abundantly clear. As Harvard Business Review’s Global Supply Chains in a Post-Pandemic World states, “The obvious way to address heavy dependence on one medium- or high-risk source (a single factory, supplier or region) is to add more sources in locations not vulnerable to the same risks.”

6. Factoring suppliers into evaluation and planning as a top priority

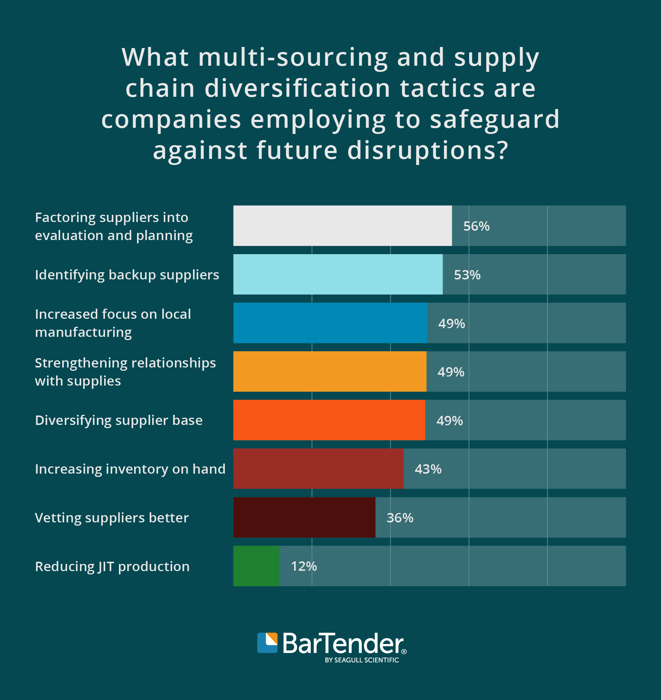

With regard to multi-sourcing and supply chain diversification tactics companies are employing to safeguard against future disruptions, survey participants noted factoring suppliers into evaluation and planning as being the biggest priority, followed by identifying backup suppliers.

While it’s a given that supply chains are highly dependent on suppliers, when operations run smoothly, it can be taken for granted. The abrupt disruptions caused by COVID-19 seem to have made it abundantly clear that adequate planning must involve factoring suppliers into the equation and that to neglect to do so will only result in inaccurate planning and future disruptions.

7. Focusing less on sourcing from lower-cost suppliers in favor of suppliers with more flexibility and resilience

We asked survey participants to indicate the extent to which they agree with the following statement: To safeguard against future supply chain disruptions, my company is focusing less on sourcing from lower-cost suppliers in favor of suppliers with more flexibility and resilience. The majority said, “Strongly agree” or “agree”.

Cost will always be one of the main drivers when choosing suppliers, but another lesson from this past year that organizations took note of is that it is not the only driver. The focus has shifted from seeking the lowest-cost supplier to sourcing a supplier with more flexibility and higher resiliency.

8. Adopting new technologies to enhance supply chain visibility

Regarding actions companies are taking or considering to enhance supply chain visibility, survey participants noted adopting new technologies and increasing communication as two of the biggest priorities. Interestingly, these two priorities are highly interrelated.

New technologies geared toward enhancing supply chain visibility also increase communication in the supply chain. Improved visibility and communication allow organizations to collect better information and, in turn, improve their supply chain planning and execution. The results of enhanced supply chain visibility range from improved efficiency and reduced risks to increased profits and better customer satisfaction.

9. Prioritizing employee health and wellbeing as an imperative

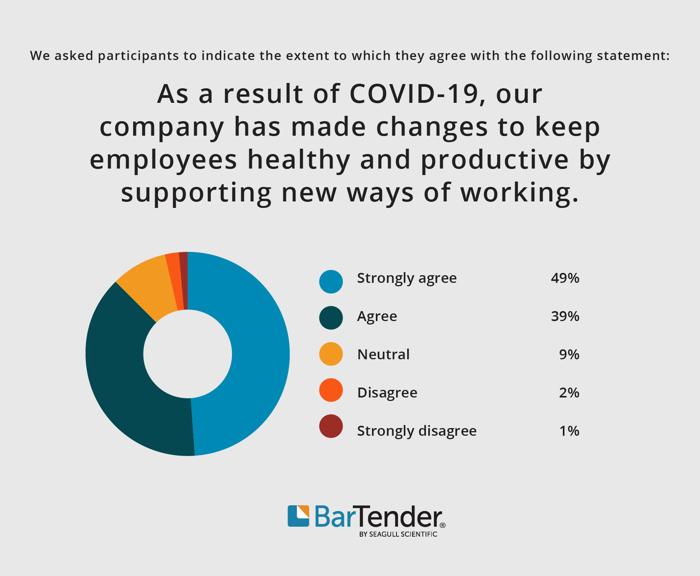

In addition to the strategies above, the majority of survey participants noted that their company has made changes to keep employees healthy and productive by supporting new ways of working.

We asked survey participants to indicate the extent to which they agree with the following statement: As a result of COVID-19, my company has made changes to keep employees healthy and productive by supporting new ways of working.

Nearly half of those surveyed responded they strongly agree and another 38% agree that because of COVID-19, their company made changes to support new ways of working with the express intent of keeping employees healthy and productive.

Overall, this trend is seen across industries with McKinsey reporting that “96% of companies globally provided additional mental-health resources to employees.” Companies realize the well-being of their employees impacts the supply chain and bottom-line figures in several ways. A healthy workforce results in greater productivity, better work quality and improved relationships. These benefits are not only felt at the micro level but positively impact the entire supply chain.

Safeguard your supply chain with BarTender

Having a secure, reliable labeling system can help to proactively safeguard your business against future supply chain disruptions. BarTender® software integrates with existing systems and workflows, enabling organizations to improve safety, security, efficiency and compliance. To learn more, contact us or download the BarTender free trial for a complete label management system.